Model 722 comes standard with 4″x10″ Wheels and a 21″ wheel width.

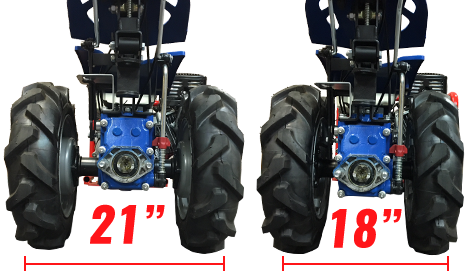

Model 722 comes standard with 4″x10″ Wheels and a 21″ wheel width. This tractor is recommended for BCS 20″ and 26″ tiller widths. With the 26″ tiller, the 722’s standard wheel width will not pose any issues as it is well within the operational width of the tiller.

Performing primary tillage with the 20″ tiller should not pose any issues either. This is due to the fact that BCS tillers provide enough “spillage” to cover the 1/2″ of tire tracks that extend past the tiller on either side.

Issues may arise, however, when performing inter-row cultivation with a 20″ tiller and standard 21″ wheel width. While the hood of the tiller keeps your crops’ leaves and stalks safe from the quickly spinning tines, the extra 1/2″ of tire sticking out has a tendency to grab overhanging foliage with predictable results.

A simple solution is built in to the standard 4″x10″ wheel design – no extra purchase necessary! The tire is mounted on an outer rim equipped with two sets of tabs and a removable center hub/”dish”. The dish may be bolted in various configurations onto the two sets of tabs to provide a variety of wheel spacings. By removing the dish, flipping it over, bolting it back onto the same set of tabs, and reinstalling the wheel on the opposite side of the tractor, you will have reduced the 722’s wheel width from 21” to 18” – well within the width of the 20” tiller and away from the foliage.

The Post-It note is stuck to the INSIDE of the tire. After completing all the steps, this will now be the OUTSIDE of the tire, as it will need to be installed on the opposite side of the tractor.

Tools required: 17mm socket (or wrench), two 13mm sockets (or wrenches)

Step 1: Remove the wheel from the tractor using a 17mm socket. It is recommended that you work with one wheel at a time so that it is easier to keep track of which parts have been flipped.

Step 2: Remove the inner dish from the outer rim using a 13mm socket and wrench to remove the four bolts.

Step 3: Flip the dish and reinstall it on the same tabs from which it was removed. Don’t forget to reinstall the lock washers.

Step 4: Set first wheel aside and repeat process for second wheel.

Step 5: Reinstall wheels on OPPOSITE sides of the tractor. There will not be enough clearance to remount the wheels to their original sides.

This will now be the OUTSIDE of the tire, as it will need to be installed on the opposite side of the tractor from which it was removed.

After flipping the inner “dishes” and reinstalling the wheels, Model 722’s wheel width has been narrowed by 3″.

Now you’re ready to take that 20″ tiller in between rows and right up next to your crops for inter-row cultivation.

Happy gardening,

The BCS America Team

If you have questions or concerns about the content of this article, please email info@bcsamerica.com.

Step 2: Remove the inner dish from the outer rim using a 13mm socket and wrench to remove the four bolts.

Step 3: Flip the dish and reinstall it on the same tabs from which it was removed. Don’t forget to reinstall the lock washers.

Step 4: Set first wheel aside and repeat process for second wheel.

Step 5: Reinstall wheels on OPPOSITE sides of the tractor. There will not be enough clearance to remount the wheels to their original sides.

This will now be the OUTSIDE of the tire, as it will need to be installed on the opposite side of the tractor from which it was removed.

After flipping the inner “dishes” and reinstalling the wheels, Model 722’s wheel width has been narrowed by 3″.

Now you’re ready to take that 20″ tiller in between rows and right up next to your crops for inter-row cultivation.

Happy gardening,

The BCS America Team

If you have questions or concerns about the content of this article, please email info@bcsamerica.com.